In the flat glass industry, ever more expensive kinds of glass are being processed. The variety is increasing even as production throughput time is dropping, especially for LAMI. This means that the value of the partial sheets that are left after cutting is also increasing. What are you supposed to do with these?

Anyone who does not use residual plates is just giving money away!

The worst solution: storing these remnants "somewhere" and eventually disposing of them because you have no concept how you can include them in optimizations and increase yield.

A good solution is the use of a mechanical residual plate management system. But these storage systems represent significant investments. They are not the optimal solution for every company.

Managing residual plates intelligently: achieve the best possible yield with the A+W Residual Stock Manager.

Clever software –best yield

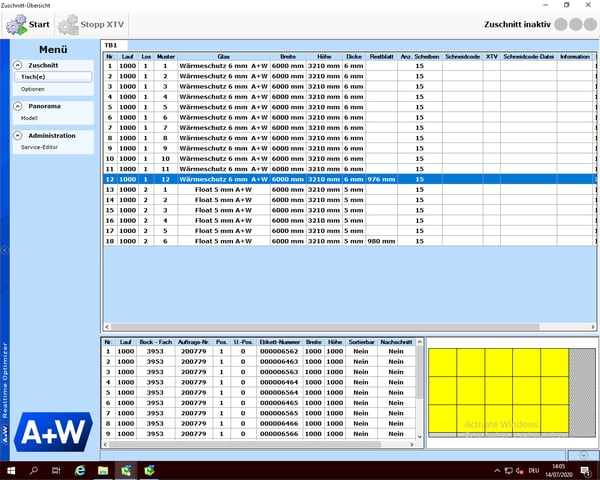

Now A+W is approaching this problem with a brand-new software solution – this is a big win for many companies. The manual residual plate management system A+W Residual Stock Manager (RSM) uses harp racks and A/L racks for temporary storage of the first cuts and thus achieves the best possible yield when combined with the A+W Realtime Optimizer.

The first cuts are taken manually from the cutting table and placed on racks, where the RSM assigns rack and slot and saves these in the database. From now on, the system "knows" which first cuts of which glass type in which size are on which rack and are available for optimization.

If the RSM discovers during a future optimization that a residual plate it manages can be used with good yield, it will incorporate this first cut into the optimization. The remnant can be used easily together with a jumbo sheet. Several RSM plates can also be used in an optimization and optimization across several cutting tables is possible. With use of a mechanical residual plate management system, the use of the RSM allows a further increase of the yield.

When using A-/L-racks for remnant storage, you have to consider that only the outermost plate on the rack can be used. However, the RSM considers this particularity and achieves the best possible yield even with such racks.

Clear screens show the machine operator in cutting from which slot or rack he should take the first cuts and where he has to store newly created residual sheets.

Your benefits:

- Residual plates are incorporated into ongoing optimizations for the best yield

- No investment in expensive mechanical systems

- Use of a residual plate storage system managed by the A+W Residual Stock Manager possible across several cutting tables

- Use in combination with mechanical systems is possible with good results

- Reduction of manual search efforts

- Timely re-processing

- Consideration of sequence to minimize set-up time