BarteltGLASBerlin is a family-owned company, a glass finisher that develops exciting products for the future based on traditional values. A company that not only incorporates developments, but initiates and advances them. This is how proven concepts, craftsmanship, and a constant readiness to innovate create new products and services that not many glass finishers can offer.

It’s no accident that BarteltGLASBerlin was an early A+W customer. Thirty years ago, the consistent use of software was not yet a matter of course in glass finishing. In this respect, BarteltGLASBerlin was also one of the pioneers in the flat glass industry. This Berlin glass finisher not only uses A+W software successfully, it has also helped enhance the software with its valuable suggestions from practical use.

Technology and design

In a 13,500 square meter facility in Berlin Marienfelde, BarteltGLASBerlin employs 120 people who produce high-quality flat glass products for architects, interior designers, facade builders, manufacturers of exquisite glass-metal constructions, and trade show builders. The company’s products include technical glass as well as fascinating designer glass, glass cabinets, and complex ensembles. State-of-the-art processing techniques make possible, by themselves or combined with one another, an unbelievable range of products.

Who says that LAMI has to consist of just two pieces of glass and foil? For example, MeshArt™ enables a variety of visual, function, and design-technical applications in interior and exterior use – thanks to the use of different foils in new designs. BarteltGLASBerlin packs state-of-the-art woven plastic and materials between foils and combines such structures with digital printing on request: LAMI is one of the company’s most important technologies. One of the most important tasks of this high-performance LAMI system expanded in 2019 is the manufacturing of technical glass such as vacuum laminates, switchable glass, shatter-proof glass, and a variety of other laminated constructions.

Top-quality glass processing

High-quality glass products frequently require many processing steps. One of BarteltGLASBerlin’s greatest strengths is that all manufacturing and assembly steps are done in-house by experienced technicians with constant quality control. TG or TLG in LAMI? Or interior elements with several drill holes, corner notches, and perfect edge processing? Painted or with ceramic digital printing?

At BarteltGLASBerlin, such constructions are produced in-house, from cutting and complete manufacturing to shipping with the company’s own vehicle fleet, and if desired, including professional installation, something for which BarteltGLASBerlin is a well-equipped, knowledgeable partner.

BarteltGLASBerlin also has a metalworking shop in its own metalworking department; this shop has state-of-the-art CNC processing machines and welding workstations so that projects such as shop facades, display windows, door systems, and other glass-metal constructions can be handled in-house from start to finish, from project consulting to manufacturing to installation on-site.

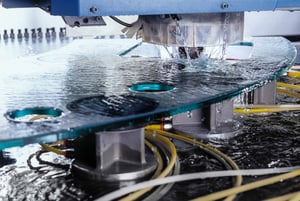

The grinding shop can perform very precise, fast CNC processings, controlled by intelligent A+W interfaces. Milling, drilling, shape edge grinding, shaped edges, facets, fluted bevels, surface finishing, engraving – with its networked machine park, BarteltGLASBerlin can do almost any kind of glass finishing – top-quality processing is this company’s answer to the ruinous price wars. The TG furnace and modernized LAMI system enable quick production of all safety glass.

These high-tech systems require skilled operation. “One key to success is our motivated, welltrained employees,” explains Commercial Business Manager Julia Geburzi-Horn. “That’s why we train them”. BarteltGLASBerlin trains people so well that the company has won several awards for this.

IT-controlled company

BarteltGLASBerlin was one of the first companies to network comprehensively with A+W software, from quotation creation to order entry to production and delivery planning. All orders are recorded in Sales with the A+W Business ERP system, transferred automatically to the A+W Production production system, and produced with the greatest efficiency in a continuously automated production environment. In technical order entry, the A+W CAD Designer is integrated completely into the entry system; the person entering the order also “constructs” complex lites, free shapes based on stored templates or the digitalization of template materials.

In each workplace, A+W Production Terminals provide the necessary information, e. g. lite data, the necessary processings, follow-up processing. In an IT system that can map all parts, processings, shapes, etc. of highly complex products, with appropriate configuration, production papers are largely superfluous. Labels save all required information, which is obtained from the production database with a simple barcode scan and visualized on info terminals for information, control, and inspection.

CAM-DXF: intelligent interface for CNC machines

The production data that is provided to the machines by A+W Production not only serves to inform the machine operator, but also to control the CNC processing systems. The processings are entered with the A+W CAD Designer or with technical order entry in A+W Business and then exported into the CAM-DXF interface format, which was developed by A+W in cooperation with leading machine manufacturers. With this technology, from technical order processing, a CAD file is sent to the CNC machine; in addition to the usual geometric data for grinding, hole drillings, cutouts, etc., this file also contains all machine parameters, for example for selection of the tools, alignment of the sheet, and suction or stop positioning.

The CAM-DXF file is transmitted to the CNC center, where all machine processes are now handled completely automatically. No more time-consuming, expensive programming work is required. “This reduces throughput times in processing enormously,” explains IT Manager Sascha Reinelt, “for example on the Forvet drilling machine and the new CMS processing center”.

Barcode control: where is my lite?

One of the most important new functions for the BarteltGLASBerlin team is comprehensive lite tracing. Thanks to systematic plant data collection (PDC), it is clear at all times which lite is where, which processings have already been completed, and what must still be done. Technical Business Manager Robert Horn says, “A+W Barcode-Tracking has made our entire production organization more efficient and transparent. Information paths are shorter, there are fewer questions, and no time-consuming searching”.

Since all PDC information is reported back to the A+W Business ERP system, the employee in order processing can always provide customers with an answer to the question “where is my lite?” – the specification of the order number is enough. Quick and reliable – this fits perfectly with BarteltGLASBerlin’s service philosophy.

On the path to Industry 4.0

In the future, the management team that includes Robert Horn and Julia Geburzi-Horn wants to further automate the company and increase the degree of digitalization. An important step in this direction was taken in order processing with the introduction of the A+W iQuote Webshop. Selected customers are currently using the system successfully, and it will soon replace order entry via Web browser, e-mail, and fax. Customers place their orders based on BarteltGLASBerlin’s current database. This reduces the entry work for both parties – the orders are checked technically and all parameters are correct.